Maintenance of PEB's- Explained and Simplified

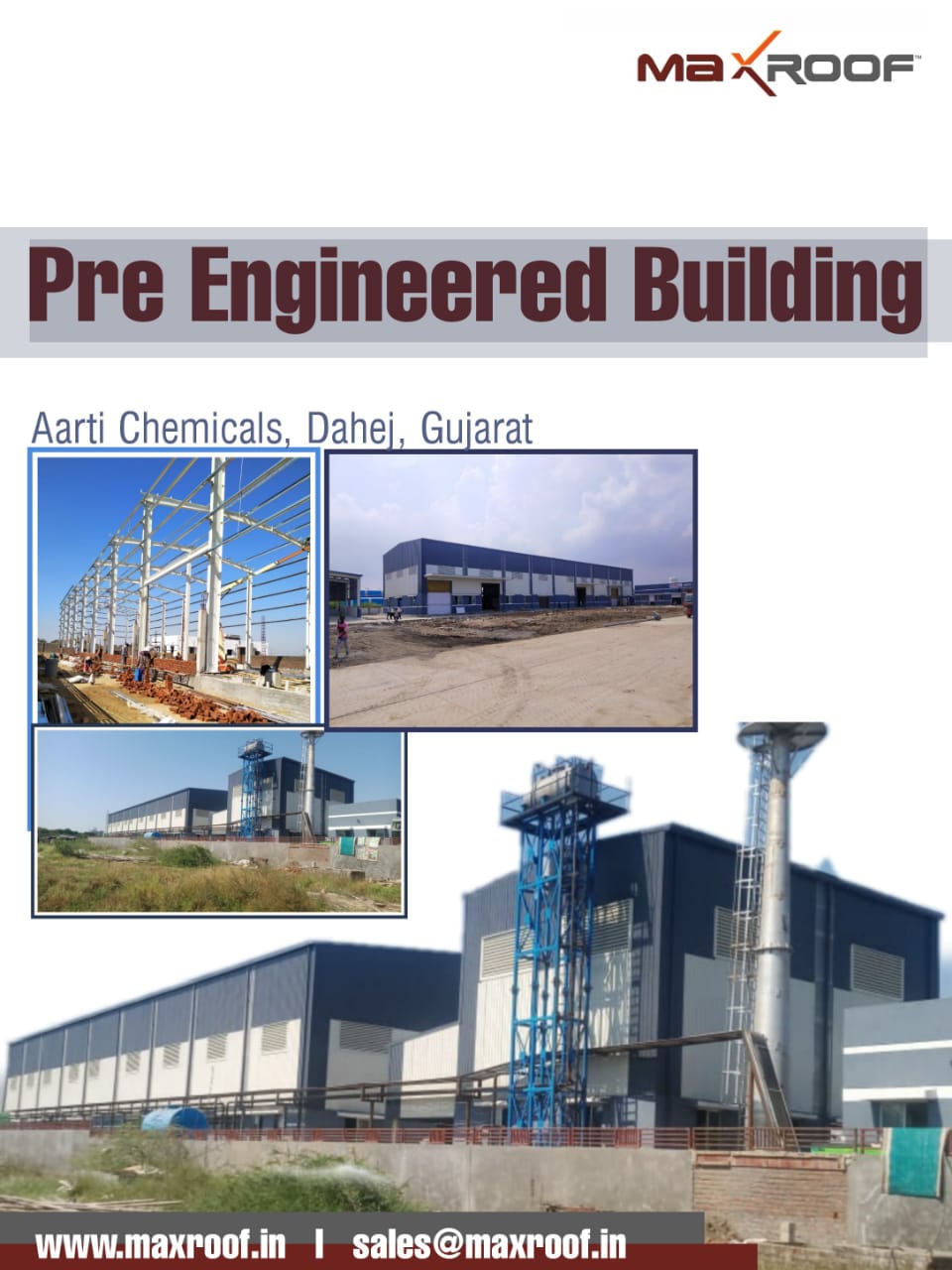

According to many manufacturers, pre-engineered buildings are a revolutionary approach to pace the construction process. Usually, pre-engineered metal building manufacturers make a PEB according to the exact size of a building, which gives them enough time for construction. Pre-Engineered Buildings are known to be strong and versatile. They are also widely in demand for their unique quality of being mobile. These durable buildings can also withstand harsh weather, which makes them an ideal choice for construction. But like any other buildings, PEBs also require timely maintenance to stand strong.

How to maintain Pre-Engineered Buildings?

1. Cleaning Regularly

Accumulation of debris and undesired items in the building areas could cause damage to the structure. The accumulation of dirt in tight spaces, as well as the formation of molds, can trap moisture and cause the material to corrode prematurely. Hence, gutters, roof sheets and downspouts should be cleaned regularly. This can be done even with a low-pressure water hose and a cleaning solution. Aside from preventing damage, cleaning the building also helps it to keep its visual appeal for a longer amount of time.

2. Proper Maintenance of the fasteners

The fasteners that hold all of the building’s elements together might also be the

cause of its demise. If the fasteners are left loose and not tightened properly,

it leaves a space for water to seep into the building’s frame, causing the

structure to corrode or rust more quickly.

Fasteners that have been damaged in any manner should be repaired or changed

right away, since they may jeopardize the structure’s strength in that area.

This can also have an effect on the load distribution in the entire structure

and could result in unanticipated damage.

3. A Fresh Paint Job

A Pre-Engineered Buildings exterior is extremely resistant to harsh weather, UV radiation, corrosion, etc. However, if the building is located close to the sea or isn’t cleaned properly, then there are high chances of corrosion. Small patches can become the beginning point of corrosion, which can subsequently spread throughout the building. To prevent this and keep the structure protected, it is a good idea to cover these areas with paint.

4. Accessory Maintenance

Along with routine maintenance of the PEB, all of the building’s accessories, such as doors, rolling shutters, and vents, must also be maintained. The frequent impact of the doors on the walls might cause the structure to deteriorate. To prevent this, one must lubricate the doors’ hinges and locks regularly, and ensure that they don’t swing all the way back against the wall. Similarly, if there are sliding doors, the guiding channels should be cleaned frequently to ensure that they run smoothly. Along with that, regularly lubricating the moving shutters and applying grease to the vertical guides, can increase the soundness of the structure.

Excellent durability is one of the reasons for the popularity of PEBs. And this durability can be improved further by taking excellent care of the building and doing regular maintenance. Proper maintenance of pre-engineered structures will not only ensure that the structure lasts long but it will also save money that will have to be spent on repairs.